Get your free Melbourne Electrician quote today!

Our team of Melbourne Electricians is here to help you with any questions or concerns you may have. We’re committed to providing you with the best possible service and support.

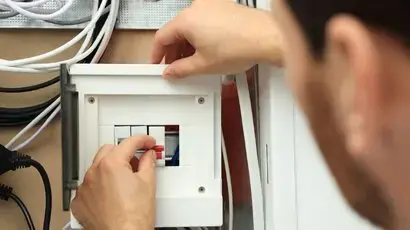

Circuit breakers are essential to electrical safety, guarding against potential hazards by interrupting faulty currents. This article delves into their function and importance in maintaining a secure electrical environment.

Imagine a circuit breaker as your electrical system’s bodyguard. Its job is to cut off electricity automatically if something goes wrong, like an overload or a short circuit. By doing so, it prevents damage and significantly lowers the risk of fires or other hazards.

Circuit breakers are everywhere—from homes to offices and commercial complexes. They play a critical role in keeping electrical systems safe by curbing issues from excessive current flow. Be it a small breaker for a single appliance or a hefty one in a big setup, they ensure smooth and safe operations everywhere.

Circuit breakers kick in by cutting off the electrical current at the first sign of trouble. This not only prevents equipment damage but also minimises fire risks, boosting overall safety. Knowing how they work is crucial for ensuring your electrical setup remains safe and reliable.

Definition and Purpose of a Circuit Breaker

A circuit breaker is an electrical safety device designed to protect an electrical circuit from damage caused by a short circuit or overload. Its function is to interrupt current flow to prevent overheating and potential fires. Acting as an automatic electrical switch, a circuit breaker is triggered when a fault occurs, safeguarding electrical systems and the power distribution grid.

Troubleshooting Tips for Common Issues

If a circuit breaker frequently trips, it could indicate an overloaded circuit, a short circuit, or possibly a faulty breaker. D disconnect all devices on the affected circuit and reset the breaker to troubleshoot. Reconnect devices individually to identify if a particular device is causing the overload. If the breaker trips with no load, this may point to a short circuit within the wiring or a malfunctioning breaker.

For breakers that don’t stay reset, the issue might be with the breaker itself or a persistent fault in the circuit. Carefully check the electrical current with a multimeter to ensure it aligns with the expected values for the individual circuits. If discrepancies are found, professional assessment might be necessary. We always recommend speaking with a qualified electrician.

Indications for Circuit Breaker Replacement

Circuit breakers are durable, but they do not last forever. Indications that a circuit breaker requires replacement include a breaker that won’t stay reset, signs of physical damage such as cracks or burnt areas, or a breaker that feels hot to the touch.

If the breaker cannot carry its rated load or trips without a clear cause, it is likely time for a replacement. In such cases, mainly when dealing with single-pole or double-pole circuit breakers, which are fundamental to household safety, it is crucial to consult a qualified electrician to ensure proper handling and adherence to safety standards.

Protect Your Electrical System with Expertise

Rely on WP Electrical to safeguard your electrical system; we prioritise safety and efficiency. Whether it’s for residential low-voltage needs or high-demand industrial setups, having the right circuit breaker is crucial in handling continuous current and avoiding mishaps.

At WP Electrical, we understand the intricacies of power systems and the critical role that circuit breakers play. Our team of certified professionals is adept at handling all electrical components with precision and care. We specialise in various electrical domains, from installation to maintenance, guaranteeing that your system operates at its best.

Keep the safety and performance of your electrical infrastructure strong. Reach out to WP Electrical for expert electrical services and comprehensive safety check-ups. With our knowledge and skills, we’ll ensure your power system is robust, reliable, and ready to handle the demands of modern electrical consumption. Contact us today to safeguard your electrical system with the expertise you deserve.

Published by: Pascal Harb17 October 2025