Get your free Melbourne Electrician quote today!

Our team of Melbourne Electricians is here to help you with any questions or concerns you may have. We’re committed to providing you with the best possible service and support.

Protect your employees and your business from electrical hazards with a comprehensive electrical maintenance program. Learn about the different types of maintenance, the role of a qualified electrician, and best practices for safe work procedures. Discover how to create a collaborative approach to electrical safety in your workplace.

Did you know that electrical hazards cause around 30 yearly injuries or deaths in Australian workplaces? That’s a sobering reminder of the importance of electrical safety. Safe electrical systems and equipment are fundamental to creating a healthy and productive work environment. It’s not just about worker well-being but also business continuity. Electrical accidents can disrupt operations, damage equipment, and incur significant costs.

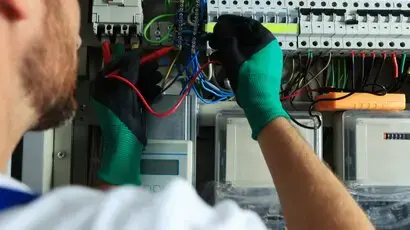

Proactive electrical maintenance is a key strategy to prevent these incidents before they become serious. This involves regularly inspecting and testing electrical equipment and using residual current devices (RCDs) for added protection. By identifying and addressing potential problems early on, like faulty wiring or damaged cords, businesses can ensure a safe working environment and compliance with electrical safety regulations.

Electrical Hazards in the Australian Workplace

In Australian workplaces, electrical hazards are ever-present, posing serious risks to both safety and business flow. Issues like faulty wiring, overloaded circuits, and damaged gear are all too common. These can lead to dire outcomes, including severe injuries or even fatalities.

10 Electrical Safety Tips

Remember, even with a comprehensive maintenance program, electrical safety requires vigilance. Here are ten electrical safety tips for everyone in the workplace:

- Never attempt electrical work unless you are a licensed electrician.

- Report any damaged electrical cords, outlets, or switches to a qualified professional immediately.

- Don’t overload electrical outlets or extension cords.

- Use only electrical equipment that has been tested and tagged as safe.

- Water and electricity don’t mix. Never use electrical equipment with wet hands or in wet environments.

- Unplug electrical equipment before cleaning or performing maintenance.

- Be aware of your surroundings and watch for overhead power lines outdoors.

- Invest in personal protective equipment (PPE) such as insulated gloves and mats when working around electricity.

- Always follow the manufacturer’s instructions for using electrical equipment.

- If you experience an electrical shock, don’t panic. If possible, remove the electrical source and call for help immediately.

Maintaining a Safe Electrical Environment: A Collaborative Approach

A well-designed electrical maintenance program is the foundation for a safe electrical environment, but it’s not the only piece of the puzzle. Here are additional strategies to create a truly collaborative and secure workplace:

- Safe Work Practices: Implementing safe work procedures prevents electrical hazards. This includes using lockout/tagout procedures whenever working on live electrical equipment. These procedures ensure equipment is isolated from its energy source and properly labelled to prevent accidental activation. Permit work systems for high-risk electrical work provide an extra layer of safety.

- Proper Use and Storage of Electrical Equipment: Employees must understand the appropriate use and storage of electrical equipment. Training and clear instructions are essential. Damaged or faulty equipment should be removed from service immediately and not used until a qualified electrician repairs it. Designated areas for cords and tools help prevent damage and electrical hazards.

- Personal Protective Equipment (PPE): It is vital to provide employees with the appropriate personal protective equipment (PPE) for electrical work. This may include insulated gloves, safety glasses, and electrically rated footwear. The specific PPE required will depend on the nature of the electrical work.

- Open Communication and Reporting: It is crucial to encourage open communication and reporting of electrical concerns. Employees should feel empowered to report any damaged equipment, unsafe electrical practices, or near misses without fear of reprisal. This allows for prompt corrective action and helps prevent future incidents.

By fostering a collaborative approach that integrates these strategies with a comprehensive electrical maintenance program, businesses can create a culture of electrical safety in the workplace. This empowers employees to identify and report electrical hazards, promotes safe work practices, and protects everyone from the dangers of electricity.

Safe Work, Strong Current: Electrical Maintenance by WP Electrical

Electrical hazards can trip up your workplace. Prevent shocks and downtime with WP Electrical’s expert maintenance. We inspect the equipment, test for faults (including residual current devices - RCDs), and ensure safe work practices with qualified electricians. Our commitment to electrical safety keeps your workplace humming. Contact WP Electrical today for a free quote!

Published by: Pascal Harb17 October 2025